1500℃ 가스플로패키지 Gas Flow Package

SH-FU-120TH-WG (300mm Ø120)

Gas Flow Package

1500℃ Furnace SH-FU-120TH (300mm Ø120)

| Model | SH-FU-120TH-WG |

|---|

| Furnace | SH-FU-120TH |

|---|

| Components | Gas Flowmeter 1EA |

|---|

| Stainless Steel Pipe & Connector |

| Gas Sealing Mask |

| Alumina Tube (Length 1000 mm) |

| Cat. No. | 230 V | FU120THWG230 |

|---|

? Safety Device

- -Automatic reset function incoming power cut

- -Buzzer on when set time arrived

- -Over temperature alarm

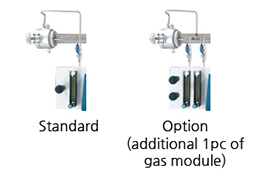

? Option

- -Gas inlet module 추가

- -가스 연결 서비스

- -MFC, BPR

-Safty Cover 튜브 안전 덮개

1500°C Tube Furnace

| Model | SH-FU-120TH |

|---|

| Max Temp | 1500℃ (2732℉) |

|---|

| Temp Controller | Programmable Controller(FC-1000) |

|---|

| Sensor | R type |

|---|

| Applicable Tube Diameter | 120 Φ |

|---|

| Heater Capa | 6.7 KW |

|---|

| Dimension Hot Zone | Length 300 mm |

|---|

Dimension External

(W×D×H ) | 680x590x760mm

26.77x23.23x29.92''

|

|---|

| Weight | 145 Kg |

|---|

| Heater Element | SIC |

|---|

| Insulation | Ceramic Board & Wool |

|---|

Electrical Requirements

230V ,50/60Hz, 1Φ | 29.1 A |

|---|

| Cat. No. 50Hz(60Hz) | FU120TH230 |

|---|

| Model | MC Series | MCS Series | MCV Series |

|---|

| Type | General | For Toxi Gas | For Vacuum |

|---|

| Flow Range | 0 ~ 1 slpm / 0 ~ 5 slpm |

|---|

Mass Flow Accuracy at

calibration conditions | ±0.6% of reading or ±0.1% of full scale | ±0.8% of reading or ±0.2% of full scale |

|---|

| Operating Temperature Range | -10 to +60°C |

|---|

| Temperature Accuracy | ±0.75°C |

|---|

| Operating Pressure full scale | 145 PSIG |

|---|

| Pressure Accuracy | Above 1 atm: ±0.5% of reading |

|---|

| Typical Indication Response Time | < 10 ms | < 100 ms |

|---|

| Typical Warm-Up Time | <1 Second |

|---|

| Monochrome LCD | Simultaneously displays

mass Flow, pressure and

temperature | Simultaneously displays mass Flow,

Volumetric Flow, pressure and temperature |

|---|

Mechanical Dimensions

(HxWxD) | 104.14x91.44x27.94mm / 4.1x3.6x1.1" | 121.92x172.72x38.1mm /4.8x6.8x1.5" |

|---|

| Gas Selectable | 98 Gas | 128 Gas | 98 Gas |

|---|

| Communication | RS-232

|

|---|

Gas Select™ Preloaded Gases

Mass Flow Controller(Multi gas selectable)

- Accessible PID valve tuning for best speed and stability.

- Custom valve orifice sizes: yields full-range stability.

- Control mass flow, vol. flow or pressure with one device.

- No warm-up: ready to control process flows in one second.

| Model | BPR Series | BPRS Series |

|---|

| Type | General | For Toxi Gas |

|---|

| Pressure Range | 1PSIG ~ 15PSIG |

|---|

| Standard Accuracy | ± 0.25% (≥ 1 psi) |

|---|

| Repeatability | ± 0.08% Full Scale |

|---|

| Typical Response Time | < 100 ms |

|---|

| Warm-up Time | < 1 Second |

|---|

| Operating Temperature | -10 to +60℃ |

|---|

| Monochrome LCD | Displays Pressure |

|---|

Mechanical Dimensions

(HxWxD) | 104.14x91.4x27.94mm / 4.1x3.6x1.1" |

|---|

| Communication | RS-232 |

|---|

적용분야- 우주소재 및 금속재료 생산 산업분야 / 세라믹, 합금, 타타늄의 열처리를 수행하는 파괴시험 연구,개발 및 생산

Destructive testing laboratories who carry heat treatment of ceramic, alloy, titanium and etc for aerospace and metallic production industries. - 니켈함금과 같은 금속류 분말을 소결하는 연구,개발 및 생산

Building companies who transforms metallic power such as nickel alloy into sintered materials by sintering. - 고분자합성물과 그라핀을 개발하는 재료공학 연구,개발 및 생산

Material technology providers who develop polymer composites and graphene materials. - 가스분위기에서 상온과 고온(1700 도)의 반복산화시험을 수행하는 우주항공용 소재 연구,개발 및 생산

Aerospace companies who perform cyclic oxidation test between high tmep to room temperature in atmosphere-controlled environment. - 재료의 연소를 통해 성분을 분석해야 하는 의료 연구, 개발

Medical and healthcare companies who need analysis of ashes and contents through combustion of materials. - 진공과 가스분위기에서 소결을 해야 하는 재료 혁신 연구 , 개발및 생산

Material innovation companies who do sintering in vacuum or in inert gases. - 인코넬 718 튜브를 소결, 소둔, 경화하는 진공전기로가 필요한 해상용 표면 인젝션 시스템 연구, 개발및 생산

Subsea and surface injection system companies who need vacuum furnace for softening cycles, annealing and age hardening of Inconel 718 tubes. - 다양한 물질을 열처리시험을 통해 분석하는 연구,개발

Analytical research labs who perform various material testing with thermal treatment. - 합금파우더를 소둔하는 의료용 임플란트 연구,개발및 생산

Medical implants manufacturers who anneal alloy powders. - 고분자세라믹부품의 소결을 하는 대학교 재료 과학 연구,개발

Material scientists in universities who do sintering materials such as polymer-derived ceramic parts. - 고체산화연료전지를 가공하는 응용과학기술 분야

Applied science engineers who process solid oxide fuel cells (SOFC). - 연소물질이 필요한 환경 화학 연구 분양

Environmental and chemical researchers who need combustion of materials. - 위험물질관리, 오염토양복원, 공기오염관리 분야

Regulatory compliance service providers in the areas of hazardous waste thermal treatment, air permitting, air pollution control, contaminated soil remediation, and hazardous waste management. - 금속 진공남땜이 필요한 금속부품 생산 분양

Metallic parts manufacturers who need vacuum brazing and heat treating for steel. - ASTM D2584에 따라 섬유강화합성물의 유리성분을 시험해야 하는 수질처리 분야

Water treatment companies who test glass content in FRP (fiber reinforced polymer) products according to ASTM D2584. - 질화갈륨 반도체 웨이퍼를 소둔하는 반도체 분야

Semiconductor manufacturers who anneal Gallium nitride (GaN) semiconductor wafer. - 다공세라믹튜브을 위한 양생과 소결방법을 연구하는 엔지니어링 분양

Engineering companies who do curing and sintering solutions in porous ceramic tubes. - 토양연소가 필요한 토목공학 분야

Civil engineers who need soil combustion. - 진공조건에서 실리카 웨이퍼를 소둔하는 연구 분야

University labs who anneal Si wafer in vacuum condition. - 탄소나노섬유(CNT) 전구의 열처리를 수행하는 화학연구분야

Chemistry research departments who do the thermal treatments (stabilization in air and carbonization in argon) of carbon nanofiber precursors. - 해상용 중유의 성분을 분석하는 해상장비제조분양

Marine equipment manufacturers who analyze ash content in marine HFO (Heavy Fuel Oil). - 화학증기증착기법(CVD) 을 이용한 그라핀기반재료를 생산하는 그라핀 연구 , 개발및 생산

Graphene solution companies who produce graphene-based materials by CVD (Chemical Vapor Deposition) method. CVD furnace - 폴리머, 옥사이드, 인산염, 황화물을 이용한 차세대 고체전지 개발분양

Solid state battery manufacturer with polymer electrolyte, oxide electrolyte, sulfide electrolyte, phosphate electrolyte and etc.

직납 운임비 지역별 차등

상품문의는 메일vls077@daum.net 로 주세요